release time:2021-08-20 16:02:39

In the previous article, Seamaty shared with you three common types of large immunoassay analyzers: fully automated chemiluminescence immunoassay analyzer, fully automated microparticle chemiluminescence immunoassay analyzer and fully automated electrochemiluminescence immunoassay analyzer. There are also maintenance methods for these immunoassay analyzers.

The fault is caused by the misalignment of the specimen rack in the track and the track can not run. Because the track is very long, and closed not easy to dismantle, generally check the horizontal lift connected to the track first. If normal, then check the track, as long as the misaligned specimen rack is removed, the fault can be eliminated.

Seamaty Veterinary Immunoassay Analyzer SMT-680V

A. Compact and light weight

Veterinary Immunoassay Analyzer SMT-680V Only 8Kg with small dimensions, space saving and fitting easily into your laboratory.

B. Minimum maintenance

SMT-680V Fluidics-free system for greater reliability, without carry over and less maintenance.

C. Easy to use

SMT-680V takes only several steps to finish the operation, increased efficiency and streamlines workflow.

2022-05-11

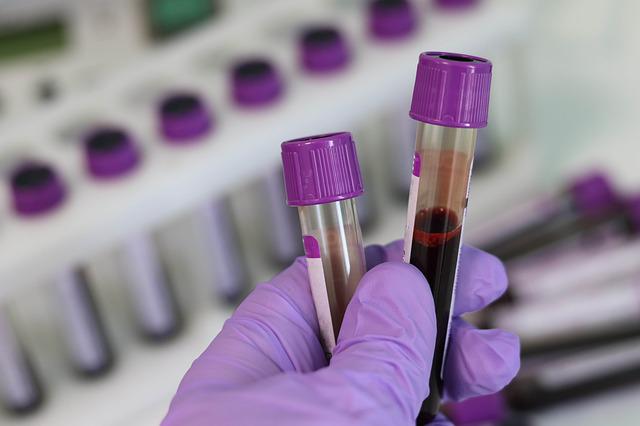

After the blood leaves the body in the natural environment, non-anticoagulated specimens will quickly coagulate and precipitate is serum. Some specimens are used a variety of anticoagulants,

2022-03-01

The COVID-19 test is now hard to find worldwide, and there are even some fake nucleic acid kits available. However, the rapid spread of the Omicron strain has led to a surge in demand for COVID-19 testing.

2021-08-23

In vitro diagnostic industry technology is very closely related to medical testing technology. the development of IVD industry is accompanied by the development of biochemistry, immunology, molecular biology, automation, information technology and other fields.