Biochemistry/chemistry analyzer is an important medical equipment for clinical diagnosis and treatment in hospitals. Through blood testing, it can reflect the changes in kidney function, liver function, electrolytes, coagulation, blood sugar and other related indicators of patients, providing an important basis for doctors to provide clinical diagnosis and treatment.

According to the type of chemical reaction, chemistry analyzers can be roughly divided into

dry chemistry analyzers and wet chemistry analyzers. Wet chemistry analyzers are the large, fully automated chemistry analyzers that we commonly see in hospitals. In primary hospitals and clinics we see more portable small dry biochemical analyzers. What are the differences between these two types of biochemical analyzers in terms of operation, use and maintenance?

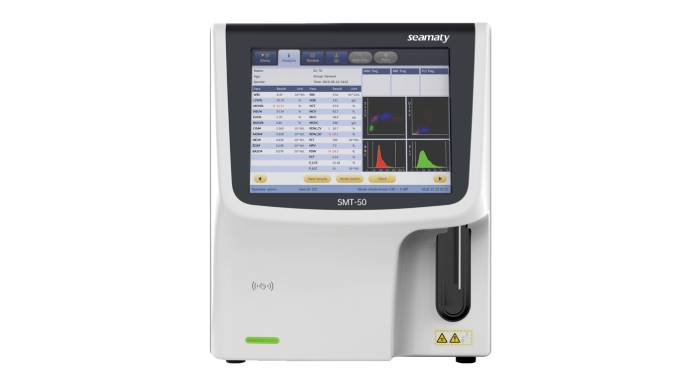

Wet chemistry analyzer use and maintenance

The wet chemistry analyzer requires a reagent check each time it is used. When the reagent quantity is insufficient, it should be added in time. Moreover, the reagents themselves have an expiration date, and need to be replaced in time if they have been left for too long. However, the wet chemistry analyzer is suitable for high-volume testing, and this biochemistry instrument can test hundreds or thousands of samples each time. This biochemical instrument is more suitable for use in large hospitals and laboratories.

As the wet chemistry analyzer contains internal piping system, in order to prevent the occurrence of pipeline blockage, water leakage, gas leakage and other phenomena, the daily maintenance work is particularly important. Check whether the cleaning solution, distilled water and diluent are sufficient before starting the machine every day. In addition, check whether the pipeline system has water leakage.

After the machine is turned on, it is necessary to check whether the reagents need to be added, flush the pipeline and make zero calibration. When shutting down the machine, flush the pipeline, empty the waste liquid bucket, clean the sample needle and stirrer. Periodically flush the piping system, sample needle, stirrer and other parts with special cleaning solution. Periodically, the optical path should be checked.

Other maintenance work can be done according to the actual work needs. Such as cleaning the air filter, using special cleaning liquid soak flush piping system, replace the filter in the liquid circuit, replace the gasket, etc.

If the wet chemistry analyzer is left idle for a long time for some reason, it is better to turn on the machine and flush the piping system 2~3 times a week regularly during the sitting period to prevent the piping from clogging. Otherwise, it is necessary to repeatedly flush the pipeline with distilled water before placing it. Then the water in the pipeline will be drained, and only after the water in the pipeline is thoroughly dried, can it be boxed and stored.

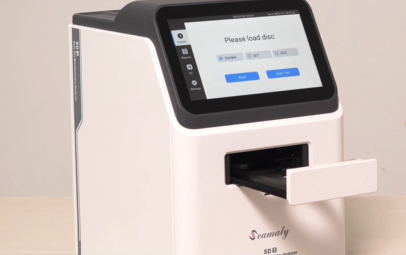

Dry chemistry analyzer use and maintenance

Dry chemistry analyzer does not need to prepare reagents when used. This small biochemistry instrument uses dry reagent strips or reagent trays already configured by the manufacturer. Since the dry chemistry analyzer itself does not store reagents and does not do pipeline cleaning, it is much easier and faster to use. The liquid sample is simply added to the dry reagent strip/tray. The blood sample is then able to penetrate through the layers of the film and after the color development reaction the corresponding color is displayed, so that the concentration of the component to be measured in the sample can be calculated.

The dry chemistry analyzer has a simpler structure because the piping system has been abandoned. Therefore, its maintenance work is also much easier. Generally speaking, it is only necessary to do regular inspection of the optical circuit and internal cleaning of the machine as needed.

If the dry chemistry analyzer is not used for a long time and needs to be left for a long time, it does not need to be opened and flushed as often as the wet chemistry analyzer. Just need to pay attention to the preservation environment of dust, moisture, high temperature and other conditions on the line. But the two machines need to be put into use after a long time, you must first carry out quality control tests. The quality control is normal before it can be put into use. Not normal must be calibrated, calibrated, quality control can be normal use only after normal.

These are the main differences between dry chemistry analyzers and wet chemistry analyzers in the use and maintenance process. Both have their own strengths, and users can choose the right chemistry analyzer according to their own conditions of use.